Wednesday, February 12, 2025

Making a Wooden Boat: A Complete Guide for DIY Builders

Making a Wooden Boat: A Complete Guide for DIY Builders

So, you want to build a wooden boat? That's awesome! It's a challenging project, sure, but the satisfaction of slipping your own handcrafted vessel onto the water is unparalleled. This isn't a weekend project, folks, but I'll walk you through the process, step by step, so you can navigate this exciting build like a seasoned captain.

Planning Your Wooden Boat Project

Before you even think about touching a saw, you need a solid plan. Jumping in headfirst is a recipe for frustration (and potentially, a very expensive pile of wood).

Choosing Your Boat Design

First things first: what kind of boat do you envision? A sleek kayak? A sturdy rowboat? A whimsical little dinghy? There are countless plans available online and in books, ranging from beginner-friendly to incredibly complex. For your first boat, I highly recommend starting with a simpler design. Don't get intimidated by the more elaborate ones just yet!

Gathering Your Plans and Materials

Once you've chosen a design, you'll need detailed plans. These plans will include diagrams, material lists, and construction steps. You can find plans online (some free, some paid), in boating magazines, or even from experienced boatbuilders. Remember to carefully review the plans to understand every step before you begin.

Next, gather your materials. This is where it gets a little pricey. You'll need:

- Wood: The type of wood depends on your design and budget. Marine-grade plywood is a popular choice for beginners due to its durability and relatively easy workability. Other options include cedar, mahogany, or oak, each with its own characteristics and price point.

- Fasteners: Marine-grade screws, bolts, and nails are essential for a watertight and durable build. Don't skimp on quality here; cheap fasteners will lead to leaks and other problems.

- Epoxy and Fiberglass Cloth: These are crucial for sealing the wood and adding strength and water resistance. Epoxy is a strong adhesive and sealant, while fiberglass cloth provides additional reinforcement.

- Tools: You'll need a range of woodworking tools, including saws (hand saws, circular saw, jigsaw), chisels, planes, clamps, sandpaper, and measuring tools. A good quality drill is also essential.

- Finishing Materials: You'll need to protect your finished boat with a suitable marine varnish or paint to prevent rot and weathering.

Building Your Wooden Boat: A Step-by-Step Guide

Okay, let's get to the fun part! Building your boat will involve several stages. The exact steps will vary depending on your design, but here's a general overview:

Step 1: Preparing the Wood

Before you start assembling anything, carefully cut and shape the wood pieces according to your plans. Accuracy is key here; any mistakes at this stage will compound as you progress. Take your time and double-check your measurements.

Step 2: Assembling the Hull

This is where the real work begins. Carefully follow the plans to assemble the hull (the main body of the boat). Use clamps to hold the pieces together while the epoxy cures. Be patient and meticulous; this is the foundation of your boat.

Step 3: Adding the Deck and Other Features

Once the hull is complete and cured, you can add the deck, seats, and other features according to your plans. Remember to use appropriate fasteners and ensure a watertight seal.

Step 4: Applying Epoxy and Fiberglass

This is a crucial step for waterproofing and strengthening your boat. Apply several layers of epoxy and fiberglass cloth, following the manufacturer's instructions carefully. Allow ample time for each layer to cure before applying the next.

Step 5: Finishing and Refinements

Once the epoxy and fiberglass have cured completely, sand the boat smooth and apply your chosen marine varnish or paint. This will protect your boat from the elements and give it a beautiful finish.

Launching Your Masterpiece!

After all the hard work, the moment has arrived: launching your boat! Choose a calm day and a suitable launching point. Take your time and be careful as you gently lower your boat into the water. Enjoy the fruits of your labor – you built that!

Commonly Asked Questions

Here are some questions I often get about building wooden boats:

- Q: How long does it take to build a wooden boat? A: It depends on the complexity of the design and your experience. A simple boat might take a few weeks, while a more complex one could take several months or even years.

- Q: How much does it cost to build a wooden boat? A: Costs vary widely depending on the size and materials. Expect to spend several hundred to several thousand dollars.

- Q: Do I need any prior experience to build a wooden boat? A: While some woodworking experience is helpful, it's not strictly necessary. Start with a simple design and take your time.

- Q: What if I make a mistake? A: Don't worry, everyone makes mistakes. Careful planning and meticulous work can minimize errors. If you do make a mistake, don't be afraid to ask for help or consult your plans again.

- Q: Where can I find more information? A: There are countless books, websites, and online forums dedicated to wooden boat building. You can also join a local boatbuilding club for support and advice.

Building a wooden boat is a challenging but incredibly rewarding project. With careful planning, patience, and attention to detail, you can create a beautiful and functional vessel that you'll enjoy for years to come. So grab your tools, gather your materials, and get ready to embark on this amazing adventure!

Step-by-Step Premium Wooden Boat Plans for Master Woodworkers

Step-by-Step Premium Wooden Boat Plans for Master Woodworkers

Hey there, fellow wood crafting enthusiasts! So, you're looking to build a truly magnificent wooden boat, something that whispers of craftsmanship and seafaring adventures? You've come to the right place. This isn't just some quick weekend project; we're talking about crafting a timeless masterpiece, a vessel worthy of your skills and dedication. We're diving deep into the details, providing you with premium plans designed specifically for master woodworkers like yourself. Get ready to roll up your sleeves, because we're about to embark on a journey of precision, artistry, and pure woodworking satisfaction.

Phase 1: Design and Planning – The Blueprint of Your Dreams

Before we even think about touching a single piece of wood, we need a solid foundation: a meticulously detailed plan. This isn't about slapping together some rough sketches; we're talking about creating a comprehensive blueprint that leaves no room for ambiguity. This phase is crucial for success. Think of it as laying the groundwork for a magnificent cathedral – a single misstep can have significant repercussions.

Choosing the Right Design

First things first: what kind of boat are we building? A sleek and speedy racing sloop? A sturdy and practical fishing dory? A classic, elegant yacht? Your choice depends entirely on your vision, your available resources, and your desired level of complexity. Consider factors like:

- Boat Length and Beam: Will it be a small dinghy or a larger vessel?

- Hull Type: Carvel, clinker, or strip plank? Each offers unique challenges and aesthetic qualities.

- Sail Plan (if applicable): Mast height, sail area, and rigging will impact performance and build complexity.

- Engine (if applicable): Will you be using an outboard or inboard motor? This influences the design of the transom and hull.

Detailed Plans and Specifications

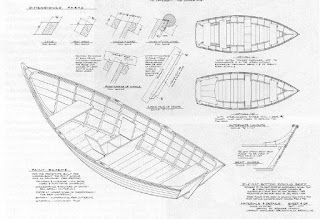

Once you've settled on a design, you'll need detailed plans. These plans should include:

- Lines Plans: These show the boat's shape and dimensions from different angles.

- Sections: Cross-sections of the hull at various points.

- Moulds and Templates: Essential for shaping the hull accurately.

- Material Lists: Precise quantities of wood, fasteners, and other materials.

- Step-by-Step Instructions: Clear, concise instructions to guide you through each stage of construction.

Don't be afraid to invest in high-quality, professional plans. A well-designed plan is your best friend throughout the entire build process.

Phase 2: Material Selection – The Foundation of Excellence

Now for the fun part: choosing your materials. The quality of your wood will directly impact the final product's strength, durability, and beauty. We're not talking about cheap plywood here; we're selecting the finest timber available.

Wood Species: A Connoisseur's Choice

Different wood species offer distinct properties. Consider factors like:

- Strength: Oak, teak, and mahogany are known for their strength and durability.

- Workability: Some woods are easier to work with than others. Cedar, for example, is relatively easy to shape.

- Rot Resistance: Teak and cedar are naturally resistant to rot and decay.

- Aesthetics: The grain and color of the wood will greatly influence the boat's final appearance.

Other Materials: Beyond the Wood

Remember, building a boat requires more than just wood. You'll need:

- Fasteners: High-quality bronze or stainless steel screws, bolts, and rivets are essential.

- Epoxy and Fiberglass (optional): These can add extra strength and water resistance.

- Paint and Varnish: Protect your beautiful woodwork from the elements.

- Hardware: This includes things like cleats, winches, and blocks (if building a sailboat).

Phase 3: Construction – The Art of Precision

With your plans and materials ready, it's time to embark on the most rewarding (and challenging) part of the project: the actual construction. This phase requires meticulous attention to detail, patience, and a steady hand.

Building the Hull: The Heart of the Matter

The hull construction method will depend on your chosen design. Whether you're using carvel, clinker, or strip-plank construction, the steps will be intricate and demanding. Accurate measurement and precise cuts are critical. Don't rush this process! Take your time and ensure each piece is perfectly fitted.

Deck and Superstructure: Adding the Finishing Touches

Once the hull is complete, it's time to work on the deck and any superstructure (cabin, cockpit, etc.). This involves carefully assembling the deck beams, planking, and any other structural components. Remember to consider the placement of hatches, ports, and other features.

Finishing and Rigging: Bringing it All Together

Finally, you'll reach the satisfying stage of finishing and rigging. This involves sanding, priming, painting, varnishing, and installing all the necessary hardware. Take pride in your work; this is where your boat truly comes to life. Rigging (if applicable) is a complex process requiring precise attention to detail. Improper rigging can compromise the safety of your boat.

Phase 4: Launching and Testing – The Moment of Truth

After months (or even years) of dedicated work, the time has come: launching your masterpiece! This moment is filled with immense pride and satisfaction. Before you take it out, however, perform a thorough inspection, making sure everything is securely fastened and watertight.

Take your time during the first few outings, carefully observing the boat's handling and performance. Make any necessary adjustments and enjoy the fruits of your labor!

Commonly Asked Questions

Q: What level of woodworking experience is required?

A: These plans are designed for master woodworkers with extensive experience in boatbuilding techniques. Significant experience with advanced woodworking skills, joinery, and composite construction is highly recommended.

Q: How long will the project take?

A: The construction time will vary significantly depending on the size and complexity of the boat, as well as the builder's experience and available time. Expect a substantial time commitment – months, or even years, for larger projects.

Q: What tools will I need?

A: You'll need a comprehensive set of woodworking tools, including but not limited to: various saws, chisels, planes, drills, clamps, and specialized boatbuilding tools. Investing in quality tools is highly recommended.

Q: Are there any safety precautions I should be aware of?

A: Boatbuilding involves working with sharp tools and heavy materials. Always prioritize safety by using appropriate personal protective equipment (PPE) such as eye protection, hearing protection, and dust masks. Follow all safety guidelines for working with power tools and adhesives.

Q: Where can I find the detailed plans?

A: The detailed plans are available through [insert link to plans or contact information here]. We offer various boat designs to suit different skill levels and preferences. Contact us for more information!

Happy building!

Customizable Wooden Boat Kits for Personalized Builds

Unleash Your Inner Shipwright: Customizable Wooden Boat Kits for Personalized Builds

The allure of handcrafted wooden boats has captivated enthusiasts for centuries. The scent of cedar, the satisfying heft of the finished hull, the sheer pride of creation – these are experiences that transcend simple boat ownership. But for many, the daunting task of building a boat from scratch feels insurmountable. Enter the world of customizable wooden boat kits: a perfect blend of pre-fabricated components and personal artistry, allowing you to build your dream vessel without the overwhelming complexity of a completely bespoke project. These kits empower you to shape your boat's design, size, and features, culminating in a truly unique and rewarding experience.

Why Choose a Customizable Wooden Boat Kit?

Forget the limitations of mass-produced boats. Customizable kits offer unparalleled flexibility. Imagine: a sleek racing skiff tailored to your precise specifications, a sturdy fishing boat perfectly suited to your local waters, or a charming rowboat designed to evoke a specific era. With a kit, you're not just assembling a boat; you're crafting a personalized masterpiece reflecting your individual style and needs. This level of customization is simply unattainable with pre-built options. You have complete control over the aesthetic details, from the wood type and finish to the hardware and rigging. The process itself becomes a journey of discovery, honing your skills and leaving you with an unparalleled sense of accomplishment.

Benefits Beyond Customization

Beyond the customization aspect, wooden boat kits offer several other compelling advantages. They often come with detailed, step-by-step instructions and comprehensive support, guiding even novice builders through the process. Many kits are designed to be manageable for individuals, reducing the need for extensive workshop space or specialized tools. Moreover, the use of pre-cut components helps minimize waste and reduces the overall building time. This efficient approach ensures that you can dedicate your time to the enjoyable aspects of woodworking, rather than getting bogged down in tedious preparation.

Exploring Customization Options: From Design to Detail

The extent of customization available varies among kit manufacturers, but generally, you'll have significant latitude in several key areas. Wood selection is often a primary point of personalization, allowing you to choose from various species like cedar, mahogany, or oak, each impacting the boat's aesthetics, durability, and weight. You can then personalize the boat's dimensions within a given range, adapting the length, beam, and draft to your intended use and storage capabilities. Further customization extends to the finish: from a natural, oiled look to vibrant varnish or even paint, you can create a truly unique aesthetic.

Tailoring Features to Your Needs

Beyond the basic hull, many kits allow for customization of additional features. Consider adding:

- Different types of seating arrangements

- Customized storage compartments

- Variations in rowing or sailing rigs

- Unique paint schemes and decorative elements

This level of detail ensures that the finished product perfectly reflects your vision and enhances your enjoyment of the boating experience. The process of choosing these options adds another layer of satisfaction to the building journey, allowing you to make conscious decisions that shape the final outcome.

Embark on Your Building Journey Today

Building a wooden boat from a customizable kit is more than just a project; it's a rewarding experience that blends craftsmanship, creativity, and connection with nature. It's a chance to escape the digital world and immerse yourself in a timeless tradition. The sense of accomplishment upon launching your hand-built boat is unmatched, a testament to your dedication and skill. Research available kits, consider your skill level, and choose a project that excites you. Begin your journey towards owning a truly unique and personalized vessel today!

Tuesday, February 11, 2025

Best Wooden Boat Blueprints for Medium-Budget Projects

Best Wooden Boat Blueprints for Medium-Budget Projects

Constructing a wooden boat is a rewarding yet challenging endeavor. The initial investment, particularly in materials and blueprints, can significantly impact the overall project cost. This article explores readily available, high-quality wooden boat blueprints suitable for medium-budget projects, considering factors such as design simplicity, material accessibility, and construction feasibility for amateur boat builders.

Understanding Your Budget and Skill Level

Before diving into blueprint selection, a realistic assessment of your budget and skill level is crucial. A "medium-budget" project is subjective and depends on geographical location and material costs. However, we can generally define it as a project falling within a range that allows for quality materials without requiring excessive expenditure. This typically excludes exotic hardwoods and necessitates careful material sourcing and potentially some degree of repurposing or reclaimed timber usage.

Similarly, your skill level influences blueprint choice. Beginners should select designs with straightforward construction methods, minimizing complex joinery and hull shapes. More experienced builders can tackle intricate designs with greater confidence.

Factors to Consider When Choosing Blueprints:

- Boat type: Simple designs like rowboats, small sailboats (e.g., dinghies, prams), or canoes are generally easier and cheaper to build than larger, more complex vessels like yachts or motorboats.

- Hull design: Simple flat-bottomed or clinker-built hulls are often more accessible to beginners than complex designs requiring advanced techniques like carvel construction or intricate curves.

- Material specifications: Blueprints should clearly specify the type and quantity of wood required. Opt for plans that utilize readily available and affordable lumber such as cedar, fir, or pine. Avoid blueprints specifying rare or expensive woods unless your budget allows.

- Construction detail: Comprehensive plans with clear diagrams, detailed instructions, and well-labeled components are essential. Avoid poorly documented plans that leave room for ambiguity.

- Support resources: Consider whether the blueprint provider offers any support or community forums. This can be invaluable for troubleshooting during construction.

Recommended Blueprint Sources and Designs

Numerous sources offer wooden boat blueprints, each with varying levels of detail and design complexity. Reputable sources generally provide high-quality, accurate plans, minimizing the risk of construction errors.

Glen-L Marine Designs:

Glen-L is a well-established provider of boat plans, offering a wide range of designs suitable for various skill levels and budgets. They cater to both beginners and experienced builders, with detailed instructions and support resources. Their simpler designs, such as the "Zip" pram or the "Wee Lassie" sailboat, often fall within a medium-budget range, utilizing readily available lumber.

Duckworks Boat Builders:

Duckworks focuses on simple, affordable boat designs, often featuring plywood construction, making them particularly accessible to beginners. Their designs emphasize ease of construction, using readily available materials and techniques suitable for amateur boat builders with limited experience. Many of their designs are specifically geared towards minimizing material costs.

Amateur Boatbuilding Magazines and Books:

Numerous magazines and books dedicated to amateur boatbuilding often publish plans or refer to readily accessible plans. These resources may not provide the same level of detailed plans as dedicated providers, but they can be a good source of inspiration and simpler designs, particularly for those willing to adapt plans to suit their skills and materials.

Online Forums and Communities:

Online forums and communities dedicated to boatbuilding provide opportunities to connect with experienced builders and access plans or modifications shared by other enthusiasts. However, always exercise caution when using plans from unknown sources, ensuring the plan's integrity and accuracy before commencing construction.

Optimizing Your Budget: Material Sourcing and Reuse

Careful material sourcing significantly influences the overall project cost. Consider the following strategies to minimize expenses:

Reclaimed Lumber:

Repurposing reclaimed lumber can substantially reduce material costs. Seek out salvaged timber from demolition sites, old barns, or even pallets. However, carefully inspect reclaimed wood for rot, insect infestation, or other damage that could compromise the boat's structural integrity.

Local Lumberyards:

Supporting local lumberyards often offers better pricing than large home improvement stores. Establish a rapport with local suppliers; they might offer discounted lumber or advice on suitable alternatives.

Negotiating Prices:

Don't hesitate to negotiate prices with lumber suppliers, especially when purchasing significant quantities of wood. Highlight the project's educational or recreational purpose to potentially garner better deals.

Alternative Materials:

Explore cost-effective alternatives such as marine-grade plywood. While not strictly "wood," plywood offers a robust and relatively inexpensive alternative, particularly for simpler boat designs. Ensure any plywood chosen is suitable for marine applications and adequately treated against water damage.

Conclusion

Building a wooden boat on a medium budget is achievable with careful planning and strategic material sourcing. By selecting appropriate blueprints from reputable sources and employing cost-saving measures, the dream of owning a handcrafted wooden boat can become a reality. Remember to always prioritize safety and structural integrity, choosing plans that match your skill level and ensuring meticulous attention to detail throughout the construction process.

Ultimately, the most important factor is choosing a project that both challenges and inspires you. The journey of building your own boat is as rewarding as the finished product itself, providing valuable skills and lifelong memories.

Classic Wooden Boat Kits with Authentic Blueprints

Rediscover the Romance of Wooden Boatbuilding: Authentic Kits and Blueprints

The rhythmic tap-tap-tap of a mallet, the scent of freshly planed wood, the satisfying heft of a perfectly shaped hull plank – these are the sensory experiences that draw so many to the captivating world of wooden boatbuilding. Forget mass-produced fiberglass; embrace the artistry and enduring legacy of handcrafted wooden boats. With a classic wooden boat kit and authentic blueprints, you can embark on a rewarding journey, creating a timeless vessel that reflects your skill and passion. This isn't just about building a boat; it's about connecting with a rich maritime heritage and crafting a piece of living history.

Choosing Your Perfect Wooden Boat Kit

Selecting the right kit is paramount. Consider your skill level, available workspace, and the type of boat that best suits your needs and desires. Beginners might find smaller, simpler designs, such as a classic dinghy or a small rowboat, more manageable. More experienced builders can tackle ambitious projects like elegant sailboats or sturdy fishing boats. Reputable kit suppliers provide detailed descriptions, including plank dimensions, required tools, and estimated build times. Carefully examine the specifications and reviews before committing to a purchase. Look for kits that offer precisely cut parts and clearly illustrated instructions, minimizing potential frustrations along the way.

Key Factors to Consider When Selecting a Kit:

- Boat Size and Type: Determine the ideal size and design that aligns with your experience and intended use.

- Kit Completeness: Verify whether the kit includes all necessary components or if you need to source additional materials.

- Blueprint Quality: Examine the clarity and detail of the blueprints – clear diagrams and precise measurements are crucial for success.

- Supplier Reputation: Choose a reputable supplier with positive customer reviews and a history of providing quality kits and support.

- Wood Type and Quality: Inquire about the type of wood used in the kit and its quality. The wood's durability and workability will greatly influence your build experience.

The Allure of Authentic Blueprints

Authentic blueprints are more than just instructions; they are historical documents, offering a glimpse into the craftsmanship and design principles of past generations. These blueprints aren't simply digital schematics; they often possess the character and detail only achieved through hand-drawn plans. They contain the accumulated wisdom of skilled boat builders, passed down through the years. Using authentic blueprints adds a layer of authenticity and historical significance to your project, connecting you directly to the rich tradition of wooden boat construction. You'll not only build a boat, but you'll also participate in preserving a valuable piece of maritime history.

Embarking on Your Wooden Boatbuilding Adventure

Building a wooden boat from a kit is a journey of patience, precision, and unwavering dedication. Each carefully shaped plank, each precisely fitted joint, contributes to the creation of a unique and beautiful vessel. Take your time, savor each step of the process, and allow the challenge to sharpen your skills and bolster your confidence. Remember that the imperfections and unique characteristics of your handcrafted boat add to its character and charm. Don't be afraid to ask for help – online forums and experienced boat builders are valuable resources. Your finished boat will stand as a testament to your perseverance and craftsmanship, a floating masterpiece born from your own hands.

Beyond the Build: The Joy of Ownership

The reward of owning a handcrafted wooden boat extends far beyond the satisfaction of completing the project. Imagine gliding across the water, feeling the gentle rocking motion and the sun warming your face. This isn't just transportation; it's a connection to nature, a source of tranquility, and a symbol of your personal achievement. Whether you use your boat for leisurely cruises, fishing expeditions, or simply admiring its beauty at the dock, your handcrafted vessel will provide years of enjoyment and a lasting source of pride. It becomes a cherished heirloom, a legacy you can pass on to future generations.

DIY Wooden Boat Building Plans for First-Time Hobbyists

DIY Wooden Boat Building Plans for First-Time Hobbyists

Constructing a wooden boat is a challenging yet rewarding undertaking, appealing to those with a passion for craftsmanship and nautical pursuits. This comprehensive guide provides a structured approach for first-time hobbyists, focusing on selecting appropriate plans, sourcing materials, mastering essential techniques, and ensuring a successful build. Careful planning and diligent execution are paramount to achieving a seaworthy and aesthetically pleasing vessel.

Selecting Appropriate Boat Plans

The initial and arguably most critical step involves selecting suitable boat plans. Inexperience dictates choosing a relatively straightforward design, prioritizing simplicity over complexity. Several factors influence the choice of plans:

Boat Size and Type:

Size is a major consideration. Smaller boats, such as dinghies or small rowboats, are significantly easier to construct than larger vessels. Their smaller scale reduces the complexity of construction, material requirements, and overall project duration. Type is equally important. Simple designs, like a flat-bottomed dinghy or a simple canoe, are ideal starting points. Avoid complex designs featuring intricate curves, multiple frames, or advanced joinery techniques.

Plan Complexity and Detail:

Thoroughly review the plans' detail and clarity. Look for plans that include comprehensive diagrams, detailed instructions, and material specifications. Ambiguous or incomplete plans can lead to significant frustration and potential errors during construction. Plans offering multiple views (top, side, cross-section) are highly desirable. Seek plans explicitly designed for beginners and clearly stating the skill level required.

Material Specifications and Availability:

Examine the materials list meticulously. Ensure the specified wood types are readily available in your region, and that you can source them at a reasonable cost. The plans should detail the dimensions, grades, and quantities of each component. Check the availability of fasteners, epoxy, and other necessary materials. Consider the ease of working with each material; some woods are easier to shape and work with than others.

Builder Reviews and Testimonials:

Before committing to a set of plans, research online reviews and testimonials from other builders who have used the same plans. This invaluable feedback can provide insights into the plans' clarity, accuracy, and any potential challenges or difficulties encountered during construction. Look for consistent positive feedback and an absence of significant reported issues.

Sourcing Materials and Tools

Once the plans are selected, acquiring the necessary materials and tools is crucial. Careful planning in this phase prevents delays and ensures a smooth construction process.

Wood Selection and Preparation:

The choice of wood significantly impacts the boat's durability, weight, and aesthetic appeal. Common choices for beginner projects include cedar, mahogany, and marine-grade plywood. Ensure the wood is properly seasoned (dried to the correct moisture content) to prevent warping and cracking. Planing and shaping the wood to the specified dimensions before assembly reduces construction time and improves accuracy.

Fasteners and Adhesives:

High-quality marine-grade fasteners (screws, bolts, nails) are essential for a durable and watertight construction. Epoxy resin is the preferred adhesive for its strength and water resistance. Choose a high-quality epoxy designed for marine applications, and follow the manufacturer's instructions carefully. Other essential supplies include wood filler, varnish, and paint, suitable for marine environments.

Essential Tools and Equipment:

A well-equipped workshop is paramount. Essential tools include:

- Hand saws (various types)

- Jigsaw or band saw

- Chisels and mallets

- Clamps (various sizes)

- Drill and drill bits

- Screwdrivers

- Measuring tapes and squares

- Planes and scrapers

- Sandpaper (various grits)

- Safety glasses and gloves

Consider renting specialized tools, like a thickness planer or belt sander, if purchasing them is not feasible.

Boat Construction Techniques

The construction process involves several key steps. Meticulous attention to detail and precise execution are crucial for a successful build.

Frame Construction and Assembly:

Most small wooden boats use a frame-and-plank construction method. This involves building the frames (ribs) first, carefully shaping them according to the plans. Then, the planks are fastened to the frames, creating the hull. Accurate frame assembly is paramount for a structurally sound hull.

Plank Installation and Fairing:

Plank installation requires precision and patience. Each plank should be carefully fitted and fastened to the frames, ensuring tight joints and a smooth, even surface. "Fairing" involves smoothing out any irregularities in the hull's surface, achieving a smooth, hydrodynamic shape. This often involves planing, sanding, and filling imperfections.

Finishing and Waterproofing:

Once the hull is complete, it needs a protective finish. This typically involves applying several coats of marine varnish or paint, providing protection against water damage and UV degradation. Careful sanding between coats is essential for a smooth, glossy finish. Proper caulking (sealing the gaps between planks) is also crucial for waterproofing.

Troubleshooting and Problem Solving

Even with careful planning, unforeseen challenges may arise during the construction process. Proactive problem-solving is crucial for a successful outcome.

Addressing Wood Defects:

Inspect wood carefully for knots, cracks, or other defects before incorporating it into the structure. Small imperfections can often be addressed with wood filler and careful sanding. However, significant defects may require replacing the affected wood component.

Correcting Assembly Errors:

Errors in assembly can sometimes be corrected with careful dismantling and reassembly. If the error is minor, adjustments can often be made without significant rework. However, significant errors may necessitate more substantial repairs or even restarting a section of the build.

Seeking Expert Assistance:

Don't hesitate to seek expert advice if you encounter insurmountable challenges. Online forums, local boatbuilding clubs, or experienced boatbuilders can provide valuable assistance and guidance. Consulting with someone experienced can save time, prevent costly mistakes, and ensure a successful project.

Safety Precautions

Boatbuilding involves working with sharp tools and potentially hazardous materials. Safety should be a top priority throughout the construction process.

- Always wear appropriate safety glasses and protective gloves.

- Use caution when operating power tools.

- Handle epoxy resin and other chemicals carefully, according to manufacturer's instructions.

- Ensure adequate ventilation in your workspace.

- Dispose of waste materials properly and responsibly.

Building a wooden boat is a challenging but immensely satisfying project. By carefully following these guidelines, first-time hobbyists can increase their chances of success and enjoy the pride of creating their own seaworthy vessel. Remember to always prioritize safety and take your time to achieve the best possible results.

Build and Sell Wooden Boats with Professional Plans

Build and Sell Wooden Boats: Charting a Course to Profit

The allure of handcrafted wooden boats is timeless. Their beauty, durability, and unique character resonate with a passionate audience, creating a lucrative niche market. This article guides you through the process of building and selling high-quality wooden boats, transforming your passion into a profitable venture. We'll cover everything from securing professional plans to marketing your exquisite creations.

Securing Professional Boat Plans

Your journey begins with acquiring meticulously crafted boat plans. Don't cut corners here; investing in professional, detailed plans is crucial for success. Skimping on plans can lead to costly mistakes and a subpar final product. Look for plans that include comprehensive blueprints, material lists, building instructions, and potentially even video tutorials. Reputable sources offer plans for various boat types, from classic rowboats to elegant sailboats, allowing you to choose a design that suits your skill level and target market. Research designers with a proven track record and positive reviews. Consider factors like the complexity of the design, your woodworking skills, and the desired build time when making your selection. Thoroughly review the plans before purchasing to ensure they meet your needs and expectations.

Choosing the Right Boat Design

Selecting the right boat design involves careful consideration. Analyze your target market: are you aiming for recreational boaters, fishermen, or a specific niche like classic boat enthusiasts? Your choice should reflect this. Consider factors such as:

- Boat type: Rowboats, kayaks, canoes, sailboats, motorboats – each has its own market and building challenges.

- Size and complexity: Start with a manageable project if you're a beginner. Larger, more intricate designs require greater skill and time investment.

- Market demand: Research the popularity of specific boat styles in your area to maximize your chances of success.

Building Your Wooden Boat Masterpiece

Once you have your plans, meticulously follow the instructions. Precision is paramount in boatbuilding; inaccurate cuts or assembly can compromise the boat's integrity and safety. Source high-quality lumber, carefully select your hardware, and maintain a clean, organized workspace. Take your time; rushing the process will invariably lead to errors. Invest in the right tools; don't skimp on quality here either. A well-equipped workshop will significantly improve your efficiency and the overall quality of your work. Consider documenting your building process through photos and videos – this can be a powerful marketing tool later.

Marketing and Selling Your Boats

With your exquisite wooden boat complete, it's time to showcase it to the world. Develop a strong online presence, utilizing websites, social media platforms, and online marketplaces to reach potential buyers. High-quality photographs and videos are essential; they should highlight the boat's craftsmanship and beauty. Network with local boat clubs and marinas to build relationships and generate leads. Attend boat shows and other relevant events to directly connect with potential customers. Consider offering customized options to cater to individual preferences and expand your market reach. Build relationships with marine retailers who might be interested in stocking your boats.

Pricing Your Boats Strategically

Pricing your boats requires careful consideration of several factors: the cost of materials, labor, your desired profit margin, and the market value of similar boats. Thoroughly research comparable boats to determine a competitive yet profitable price point. Clearly communicate the value proposition of your handcrafted boats – emphasizing the quality of materials, the superior craftsmanship, and the unique character of each vessel. Don't undervalue your work; your handcrafted boats represent a significant investment of time, skill, and passion.

Continuous Improvement and Expansion

Building and selling wooden boats is an ongoing journey of learning and refinement. Continuously seek ways to improve your craftsmanship, explore new designs, and expand your product offerings. Solicit feedback from your customers to identify areas for improvement. Embrace innovation, incorporating new techniques and materials when appropriate, to stay ahead of the curve. With dedication, skill, and strategic planning, you can transform your love of wooden boatbuilding into a thriving and rewarding business.

Stitch and Glue Boat Plans for Easy Construction

Stitch and Glue Boat Building: A Comprehensive Guide to Simple Construction

Stitch and glue boat construction represents a compelling approach to building your own watercraft, offering a blend of accessibility and robust results. This method, relying on the simple yet effective principles of stitching together pre-cut wooden strips and subsequently gluing and sealing the seams, allows even novice boat builders to achieve remarkable outcomes. This guide provides a detailed exploration of the process, encompassing material selection, construction stages, and finishing techniques, ensuring a successful and enjoyable building experience.

Phase 1: Design Selection and Material Procurement

The initial phase involves choosing a suitable boat plan and acquiring the necessary materials. Careful consideration should be given to your skill level, available resources, and intended use of the vessel. Numerous plans are readily available online and from specialist suppliers, ranging from simple kayaks and canoes to more complex designs. Select a plan that aligns with your experience and ambitions. Beginners are advised to opt for simpler, smaller designs to gain experience before tackling more intricate projects.

Choosing a Suitable Boat Plan

The selection of a suitable plan is paramount. Consider the following factors:

- Boat type: Kayaks, canoes, dinghies, and small sailing boats are all commonly built using the stitch and glue method. Choose a type that suits your needs and intended use.

- Size and complexity: Start with a smaller, simpler design if you are a beginner. Larger and more complex boats require greater skill and time commitment.

- Plan quality: Ensure the plan is detailed and easy to understand, with clear instructions and diagrams. Reputable suppliers offer well-vetted plans.

- Material specifications: The plan should specify the type and dimensions of wood to be used. This is crucial for ensuring structural integrity.

Acquiring Necessary Materials

Once a plan is selected, the next step is to procure the required materials. This typically includes:

- Marine-grade plywood: This is the primary structural material. The thickness will depend on the boat design, typically ranging from 6mm to 12mm.

- Epoxy resin and hardener: This is used to glue the wooden strips together and create a watertight seal. Choose a high-quality marine-grade epoxy.

- Stitch lines: These are typically copper or galvanized wire, used to temporarily hold the plywood strips together before gluing.

- Filler: Used to smooth out any imperfections in the epoxy joints after the stitch lines are removed.

- Wood sealant/primer: To protect the wood from moisture and provide a base for the paint or varnish.

- Paint or varnish: For the final finish, providing both protection and aesthetics.

- Clamps: Various sizes of clamps are crucial to hold the panels together during the gluing process.

- Safety equipment: Gloves, eye protection, and respiratory protection are essential when working with epoxy resin.

Phase 2: Construction Process

The construction process itself comprises several key stages, each requiring meticulous attention to detail.

Preparing the Plywood Strips

The plan will provide detailed cutting diagrams for the plywood strips. Accurate cutting is crucial for a successful build. Use a sharp saw and ensure the cuts are clean and square. Any imperfections can compromise the structural integrity of the boat.

Stitching the Panels Together

This involves using the stitch lines to temporarily hold the plywood strips together, following the plan's instructions meticulously. Ensure the stitching is even and taut, maintaining the correct shape and dimensions. The stitch lines act as temporary fasteners, allowing the epoxy to cure securely.

Applying the Epoxy

Once the stitching is complete, apply the epoxy resin according to the manufacturer's instructions. Use a mixing ratio appropriate for the chosen resin and ensure thorough mixing to avoid premature hardening. Apply a generous amount of epoxy to each joint, ensuring complete saturation of the wood.

Curing the Epoxy

Allow the epoxy to cure completely according to the manufacturer's recommendations. This typically involves a period of several hours or even days, depending on the type of epoxy used and ambient temperature. During this time, ensure the panels remain undisturbed and under appropriate clamping pressure.

Removing the Stitch Lines

Once the epoxy has cured, carefully remove the stitch lines. This may require the use of wire cutters or pliers. Take care not to damage the cured epoxy joint.

Fairing and Finishing

After removing the stitch lines, any imperfections in the epoxy joints should be filled using a suitable filler. Once the filler has dried, sand the surface smooth. This stage is crucial for ensuring a smooth and watertight hull.

Phase 3: Final Finishing and Preparation

The final stage involves applying a sealant, primer, and finally, paint or varnish to the finished boat. This protects the wood from the elements and enhances the aesthetics of the vessel.

Applying Wood Sealant/Primer

Apply a marine-grade wood sealant or primer to all surfaces of the boat. This will create a barrier against moisture and provide a suitable base for the paint or varnish.

Painting or Varnishing

Once the sealant/primer is dry, apply several coats of marine-grade paint or varnish, allowing each coat to dry completely before applying the next. Choose a durable and weather-resistant finish that will protect the boat from UV radiation and moisture damage.

Final Assembly and Fittings

If the design includes additional features such as seats, bulkheads, or decks, these should be added now. Install any necessary fittings, such as oarlocks, seats, or hatches, according to the plan's instructions.

Conclusion

Stitch and glue boat building provides a rewarding and accessible pathway to constructing your own watercraft. By carefully following a well-defined plan, selecting high-quality materials, and adhering to the construction steps meticulously, even novice builders can achieve impressive results. Remember to prioritize safety throughout the entire process, utilizing appropriate protective equipment and taking your time to ensure accuracy and precision. The pride of owning and operating a handcrafted boat built with your own hands is an unparalleled accomplishment.

Best Wooden Boat Plans for Entrepreneurs in Boatbuilding

Optimizing Profitability: Selecting the Best Wooden Boat Plans for Entrepreneurial Boatbuilders

The allure of wooden boatbuilding, steeped in tradition and craftsmanship, presents a compelling opportunity for entrepreneurs. However, navigating the complexities of plan selection, material sourcing, and market demands requires a strategic approach. This analysis delves into the crucial aspects of choosing profitable wooden boat plans, examining factors that maximize return on investment and ensure long-term success in this specialized niche.

Analyzing Market Demand and Profitability

Before investing time and resources in any particular boat plan, a thorough market analysis is paramount. This involves understanding current trends in the wooden boat market, identifying your target customer base, and assessing the potential profitability of different boat designs.

Identifying Your Niche Market

The wooden boat market is diverse, encompassing everything from classic yachts to smaller recreational vessels. Specializing in a specific niche can provide a competitive advantage. Consider these options:

- Classic Restoration & Reproduction: Focusing on restoring vintage designs or building faithful reproductions caters to a market appreciative of heritage and craftsmanship. This often commands premium pricing but requires specialized skills and access to antique materials.

- High-End Custom Boats: Targeting wealthy clientele interested in bespoke, luxurious wooden boats allows for higher profit margins. However, this demands extensive design capabilities and the ability to manage complex projects.

- Smaller Recreational Boats: Rowboats, dinghies, and smaller sailing vessels represent a more accessible market segment, potentially requiring less initial investment and offering faster build times.

- Commercial Fishing Boats (Smaller Scale): Depending on location and expertise, creating smaller, durable wooden fishing boats might present a viable option. Thorough research on local regulations and fishing practices is crucial.

Assessing Profitability: Key Considerations

Profitability hinges on several interrelated factors:

- Material Costs: The cost of lumber, hardware, and finishing materials varies greatly depending on the chosen wood species and the boat's complexity. Consider sourcing options that balance quality and affordability.

- Labor Costs: Accurately estimating the labor hours required for construction is critical. Experienced builders should factor in their hourly rate, while those starting out need to account for potential learning curves and associated time investment.

- Marketing and Sales: Effective marketing strategies are essential for attracting customers. This might involve creating a strong online presence, attending boat shows, and networking with relevant contacts.

- Pricing Strategy: Pricing should reflect the quality of materials, craftsmanship, and the overall market value of similar vessels. Competitive analysis is crucial to ensure your pricing is both competitive and profitable.

Selecting the Right Wooden Boat Plans

Choosing the right boat plans is a pivotal decision impacting every aspect of the build process. Several factors deserve careful consideration:

Plan Availability and Reputability

Numerous sources offer wooden boat plans, ranging from established publishers to independent designers. Verify the plan's completeness, accuracy, and clarity before purchasing. Look for plans that include detailed drawings, material lists, and construction instructions. Reputable publishers and designers stand behind their work and offer support.

Design Complexity and Build Time

Beginners should opt for simpler designs that allow for a learning curve without overwhelming complexity. More intricate designs, while potentially more profitable due to higher sale prices, require greater experience and longer build times, consequently increasing overhead costs. A careful balance between complexity and achievable build times is essential for timely completion and profitability.

Material Specifications and Sourcing

The plans should specify the required lumber species and dimensions. Research the availability and cost of these materials in your local area. Understanding the properties of different wood species is crucial for selecting materials appropriate for both the design and the intended use of the boat. Consider factors like durability, resistance to rot and water damage, and aesthetic appeal.

Scale and Customization

While adhering to the original design is essential for structural integrity and legal considerations (particularly when dealing with copyrighted designs), consider the possibility of offering limited customization options. This can differentiate your product in the market and potentially justify a higher sale price. However, avoid extensive modifications that compromise the structural soundness of the vessel. Experienced designers may offer consultation on feasible modifications while maintaining integrity.

Beyond the Plans: Essential Business Considerations

Building boats is only half the equation; a successful enterprise requires business acumen.

Workshop Setup and Tool Acquisition

Establish a well-equipped workshop that meets safety standards and accommodates the size and complexity of the chosen boat plans. The initial investment in tools can be substantial, but consider renting or leasing equipment where appropriate to minimize upfront costs.

Legal and Regulatory Compliance

Familiarize yourself with all relevant regulations regarding boat construction, safety standards, and sales. Compliance with these requirements is not only essential for avoiding legal issues but also contributes to a product's credibility and saleability.

Financial Planning and Budgeting

Develop a detailed business plan that includes realistic financial projections, incorporating material costs, labor costs, marketing expenses, and anticipated revenue. Secure necessary financing and establish a robust accounting system to track income and expenses.

Marketing and Sales Strategies

Craft a comprehensive marketing strategy that reaches your target audience. This might involve creating a professional website, leveraging social media, attending boat shows, and networking with potential buyers. Establish clear pricing structures and consider offering warranties to enhance customer confidence.

In conclusion, selecting the best wooden boat plans for entrepreneurial boatbuilders requires careful consideration of market demand, profitability, plan specifications, and crucial business aspects. By meticulously planning and executing each step of the process, entrepreneurs can create a sustainable and profitable business within this rewarding and specialized field.